With in-house design and delivery expertise, we deliver best-in-class Continuous Flight Auger (CFA) piling solutions, ideal for environmentally sensitive sites and cohesionless soils.

Key technical information

| Minimum diameter | 300mm |

| Maximum diameter | 1,200mm |

| Maximum pile depth | 34.5m |

CFA piling can be fast to install, suitable for most soil types and ideal for sites where noise and vibration must be kept to a minimum. Where a high-quality, consistent concrete supply is available, CFA piling can provide a cost-effective piling solution.

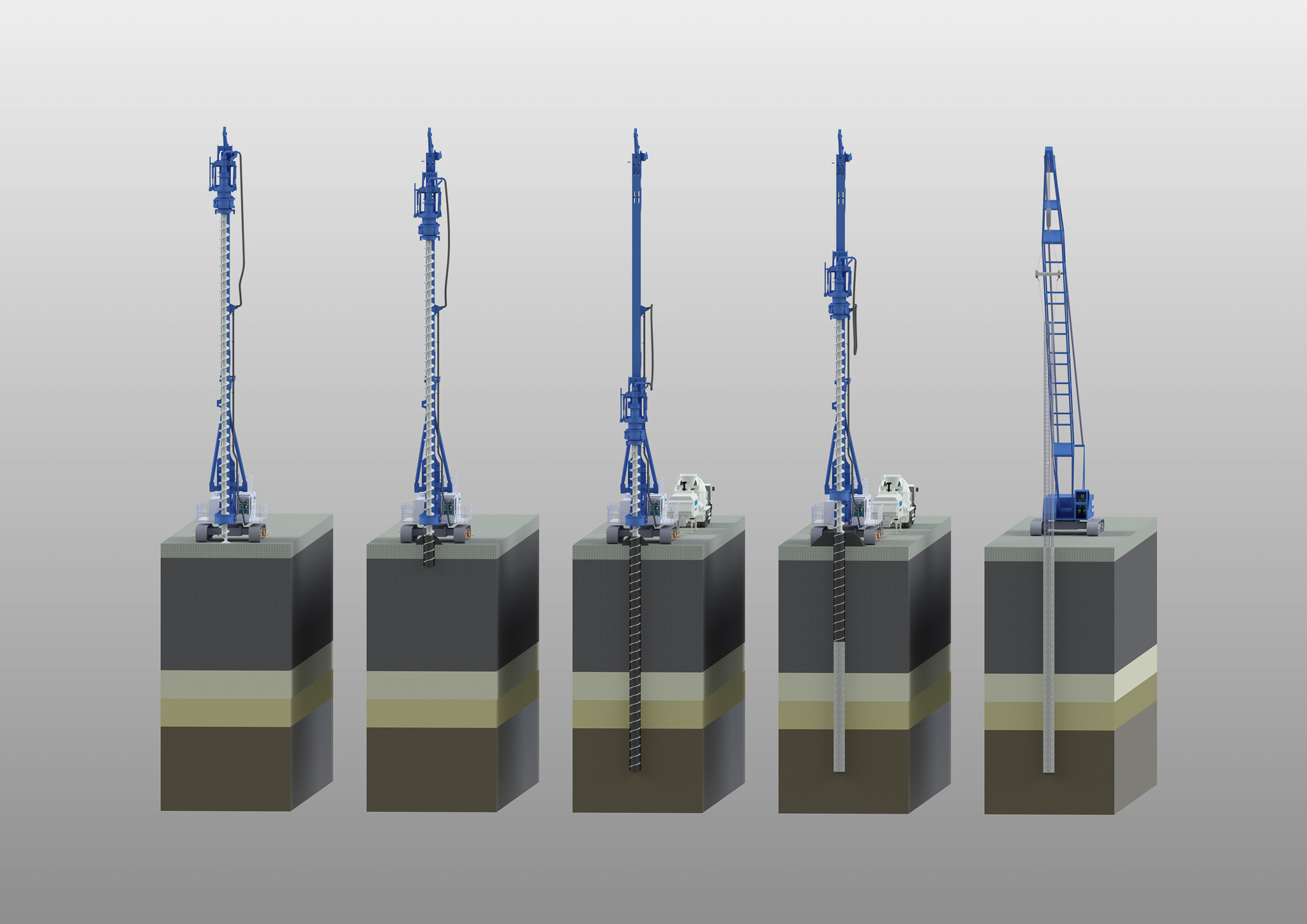

The CFA piling technique rotates a hollowed stem auger into the ground to the required depth. As the auger is withdrawn, concrete is pumped through the hollow stem under continuous pressure, forming a stable concrete shaft. This prevents ground collapse and allows reinforcement to be added.

Our modern fleet of CFA rigs is equipped with Stage V engines to deliver efficient and low-emission performance. In addition, our rigs feature advanced instrumentation that monitors depth, concrete pressure, volume and productivity in real time. This data is used to verify pile integrity and performance, providing confidence in quality and compliance.

We have developed a bespoke air-assisted drilling technique which utilises the auger stem to deliver continuous compressed air flow to the auger tip during drilling, helping to flight the excavated material up the auger and eliminating the “plugging” effect. This approach has reduced concrete blockages in the augers, improving safety, reducing concrete wastage and saving costs – particularly in weak rock conditions – across multiple projects.

Leveraging our in-house design and delivery expertise, we design bespoke solutions to meet the specific demands of the site across a range of sectors – including infrastructure, highways, rail, commercial, residential and utilities – to consistently deliver high quality outcomes for our customers.