We provide a comprehensive range of ground improvement solutions using state-of-the-art equipment, ideal for engineering brownfield sites and areas of weak compressible soils.

Our ground improvement solutions offer the following benefits:

- Simplified substructure design and construction

- Little or no spoil generated – avoiding the need for expensive disposal costs

- Reduced project time through fast design and implementation

- Around 30% of the aggregates we use come from recycled sources, supporting the sustainability objectives of our projects

- Treatment of a wide range of soil types

Learn more about our ground improvement techniques below:

PENCOL™ Rigid inclusions

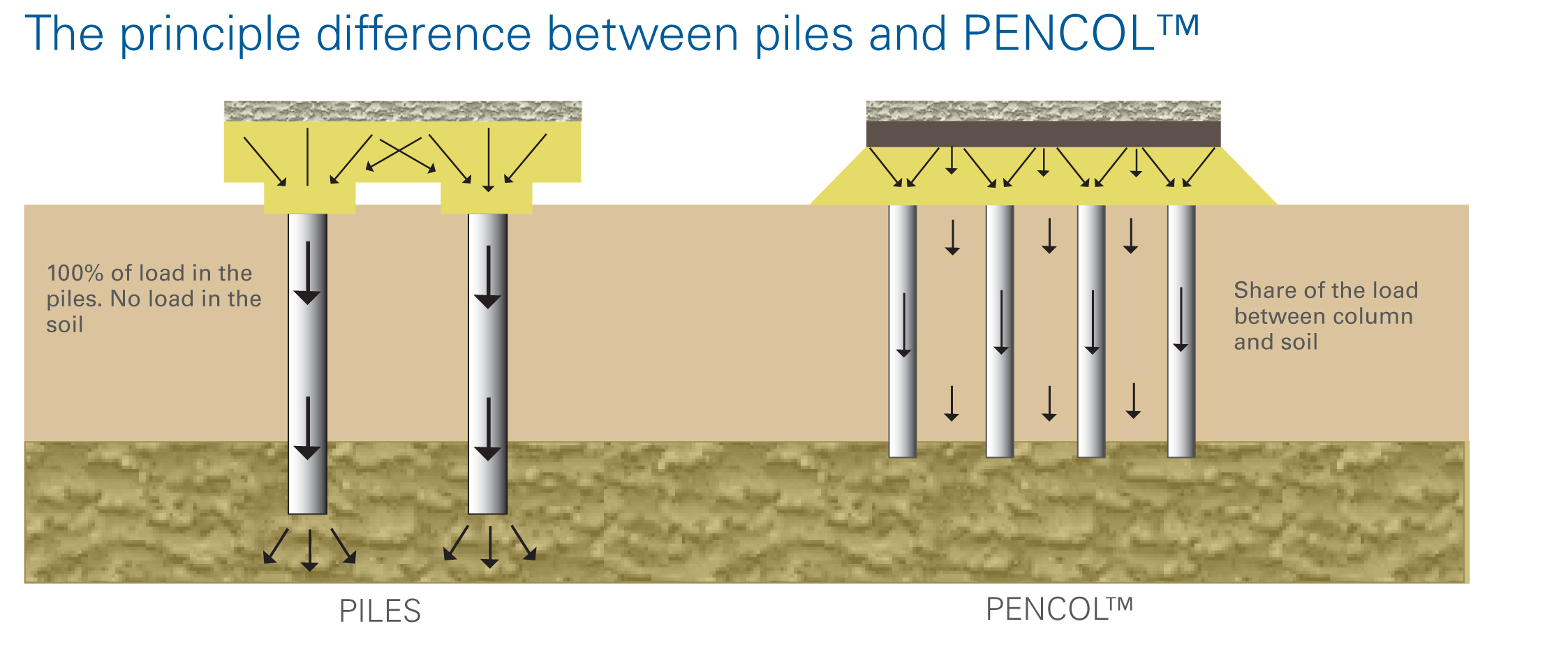

Rigid inclusions are a reliable ground improvement technique that provides an economical alternative to traditional piling. Suitable for virtually any ground condition, this method creates a composite foundation system by installing stiff, grouted columns (typically 0.3 – 0.6 metres in diameter) within weak soils.

The load from the structure is efficiently shared between the rigid columns and the surrounding soil, in conjunction with a granular Load Transfer Mattress above the inclusions. This load-sharing approach significantly increases the bearing capacity of weak soils, enhancing stability and enabling safer and more reliable construction on challenging ground.

Installation of rigid inclusions is highly efficient, generating minimal spoil and achieving rates of up to 2,500 metres per week. This makes them an ideal solution for projects where programme time is limited and sustainability is essential.

PENCOLs are unreinforced concrete elements cast directly into the ground as a type of rigid inclusion. Their installation technique compacts the ground around each PENCOL without generating spoil, minimising environmental impact. PENCOLs are typically 450mm in diameter and don’t require reinforcement, allowing for higher, more efficient installation rates.

This form of rigid inclusion is particularly well-suited for supporting lightly loaded structures that can accommodate some settlement, such as road and railway embankments, industrial and retail units, housing developments, tanks, retaining walls and slopes.

Driven piling ground improvement solution

We offer another effective type of rigid inclusion which involves the use of driven precast piles to enhance ground stability and reduce construction timelines. Driven precast piles require minimal reinforcement to facilitate lifting and driving the piles into the ground and also eliminate the need for a supply of wet concrete on-site, avoiding concrete curing delays.

These piles are manufactured in-house, at our precast factory in Bottesford, minimising on-site labour and equipment requirements. We have the flexibility to ensure that every pile meets the bespoke project specification, ensuring faster turnaround times and adaptability throughout the project to meet customer needs.

Deep soil mixing

Deep soil mixing (DSM) is a ground improvement technique that enhances the geotechnical properties of weak or unstable soils by mechanically mixing them with a cementitious blended material. Rotating piling rigs, along with mixing buckets and tools, are used to mix either a dry or wet blend of cementitious material with weak soil in various directions.

This technique increases the strength and stability of the ground, supporting excavation and enhancing load-bearing capacity for construction on top of a weak soil zone. DSM is particularly effective in soft clays, silts and peaty soils with high water content, where traditional methods may fail. It can also be used to support heavy structures, reduce settlement and mitigate risks such as liquefaction and lateral spreading.

Find out more about our other areas of expertise:

-

Vibro stone columns

Vibro stone columns are the most commonly used ground improvement method. They can be tailored to meet a wide variety of bearing capacity and settlement requirements and provide an economical and sustainable alternative to traditional piling and deep foundations. Vibro stone columns are ideal:

- In granular soils, mixed fills and cohesive soils, with bearing pressures of between 100-200kN/m2 typically achievable

- To construct columns to depths of up to 12 metres (depending upon the loading and ground conditions)

- To improve settlement by a factor of 1.5 to 3 on most projects

- To accelerate the dissipation of excess pore water generated by loading pressures

- As an alternative to more expensive piling systems – due to speed of installation and cheaper materials

- For a vast array of sectors and applications, including housing, road, rail, ports, commercial, retail, industrial, education, medical, wind farms, utilities, leisure and military projects

-

Vibro concrete columns

Vibro concrete columns are an effective ground improvement technique developed to provide integrity through weak organic soils or to provide greater settlement control than can be achieved with vibro stone columns. Vibro concrete columns are ideal:

- On contaminated piling sites where spoil removal is to be avoided, i.e. for regeneration of brownfield sites

- Where peat and organic soils preclude conventional vibro techniques

- Where founding at a high level is required to avoid piling into an aquifer

- Where short construction programmes dictate fast-track installation and high production levels

- For loads/settlement control with a load transfer platform

-

Vibro compaction

Vibro compaction is an established technique for stabilising granular soils such as loose sands, gravels and some hydraulic fills using vibroflots. The technique is primarily used for seismic mitigation and in-situ densification of loose sands up to 30 metres deep. Key benefits include:

- Enabling the construction of tank farms, ports and marine structures

- Effective for sand compaction and land reclamation projects

- Offering fast, in-situ densification of loose sands to depths of up to 30 metres making vibro compaction one of the most economical and sustainable ground improvement methods available

- Reducing the risk of liquefaction during seismic shocks by densifying sand to create a firm founding layer